Galvanized and stainless steel are two different types of materials that are commonly used to make wires and a variety...

Stainless Steel vs Galvanized Steel — Which Is Best for You?

read more

Galvanized and stainless steel are two different types of materials that are commonly used to make wires and a variety...

Single-loop baling wire has many applications, but one fact remains the same no matter what it's used for — it's one...

American steel is imported from all over the world, but the largest supplier of steel to the United States is, in...

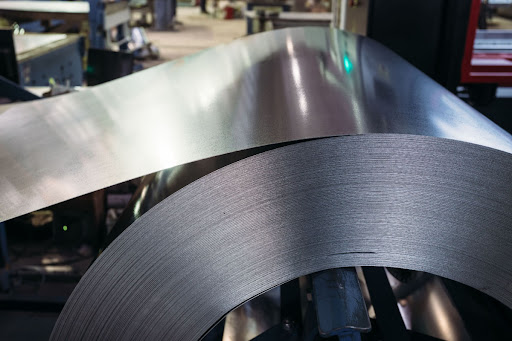

Today, galvanized steel has found widespread use in a vast array of industries and products. However, it's a...

Plain carbon steel has been modified in many ways throughout the years to enhance its effectiveness, resulting in the...