Today, galvanized steel has found widespread use in a vast array of industries and products. However, it’s a relatively new innovation in the grand scope of human history. The history of galvanized steel does not start with a single invention but was made possible by a series of scientific discoveries and experiments. Let’s take a closer look at galvanized steel’s history and how the process has evolved.

The Beginning of Galvanized Steel History

The history of galvanized steel begins long ago. People in the past have been found to use zinc and brass to create metal alloys, which are similarly used in galvanized steel. However, the origin of what we know as galvanized steel can be traced back to France in 1742. A chemist named P.J. Meloui presented a paper to the French Royal Academy outlining how iron could be shielded from corrosion by dipping it in molten zinc. This discovery led to the creation of corrosion-resistant home utensils, like pots and pans.

By this point in the history of galvanized steel, scientists understood that zinc combined with oxygen in the air faster than iron would. They knew that there was some form of electrical interaction taking place between zinc and iron, and future experiments would confirm and advance their knowledge of the process.

Galvanization Emerges

Originally, the word galvanizing did not refer to dipping steel in molten but instead the chemical process the coating offered for metal products. The term galvanized is tied to Luigi Galvani, who discovered in 1780 that a frog’s leg muscles would twitch upon entering contact with two dissimilar metals — iron and copper. This led to other experiments that would further the scientific world’s understanding of electric currents.

In 1800, Italian physicist Alessandro Volta created a stack of alternating zinc and silver plates and placed a cloth soaked with salt in between them. This experiment demonstrated that the contact of dissimilar metals was what caused the flow of electrical current.

Innovations in Galvanized Steel History

The history of galvanized steel then brings us to chemist Sir Humphrey Davy in 1824. He found that when two dissimilar metals were connected with electricity and put in water, the corrosion of one was hastened in exchange for protecting the other. Sir Humphrey believed that the copper bottoms of wooden naval vessels could be shielded from corrosion by affixing plates of zinc to them.

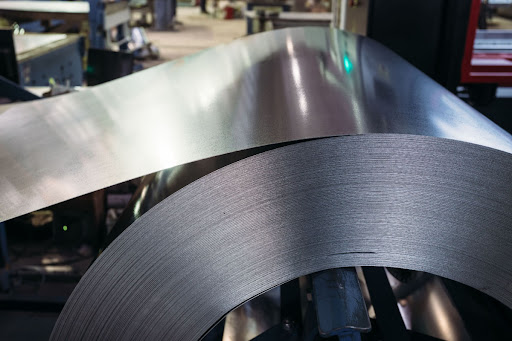

The process of dipping steel in a coat of molten zinc would finally be named galvanizing by Stanislaus Tranquille-Modeste Sorel of France, who took out a patent for it in 1836. Before, steel wasn’t treated before being dipped. Sorel’s innovation was to treat the steel first to make the iron even more resilient to the oxidation process.

The History of Galvanized Steel Continues

While one of the first recorded use of galvanized corrugated iron was by the British Navy in 1844, it has since been used in a wide range of applications thanks to its corrosion resistance and durability. Some of the uses for galvanized steel include the framework of buildings, lighting columns, vehicles, furniture, and countless other objects.

Not only is galvanized steel highly versatile, but recyclable as well. These benefits are a major reason why it continues to see so much widespread use today — it’s estimated that North America uses around 600,000 tons of zinc annually to galvanize steel.

If You’re Interested in High-Quality Galvanized Steel, Contact Wickwire Warehouse

At Wickwire Warehouse, you can find a variety of products made with hot-dipped galvanized steel. We also offer stainless steel wire, among other trusted products. For more information, reach out to Wickwire Warehouse today.